Increasing Manufacturing Productivity with an Optical Fibre Diameter Analyser

Increasing Manufacturing Productivity with an Optical Fibre Diameter Analyser

Blog Article

Enhance Your Fiber Optic Projects With an Efficient Diameter Analyser

The combination of a reliable size analyser right into fibre optic jobs works as a pivotal component in achieving precision and consistency. By helping with precise size measurements, these analysers not only boost the high quality of setups but likewise alleviate possible compatibility concerns among elements. The sophisticated capabilities of modern-day analysers simplify information collection and top quality control processes. As we explore the important attributes and benefits of these devices, it becomes obvious just how they can change job results and guarantee adherence to market standards. What remains to be reviewed is exactly how to effectively implement these analysers in your existing process.

Relevance of Size Measurement

Gauging the size of fibre optic cables is a critical job that makes sure ideal efficiency and dependability in communication systems. Exact diameter measurement is vital for different factors, largely for preserving signal honesty and lessening loss. A cable television's diameter directly affects its capability to transfer light properly; variances from the defined diameter can result in raised depletion, which affects the general performance of the network.

In addition, specific measurement is critical during the installment and maintenance of fiber optic systems. An incorrect fit in between cable televisions and ports can cause signal destruction or complete failing of communication links. By ensuring that diameters are within defined resistances, specialists can boost compatibility in between parts, leading to improved system integrity.

Furthermore, diameter measurement plays a considerable function in quality assurance during production. Uniformity in the size of fiber optic cable televisions is vital for ensuring consistent efficiency throughout various batches. optical fibre diameter analyser. This consistency aids manufacturers keep industry criteria and promotes confidence among end-users

Functions of an Efficient Analyser

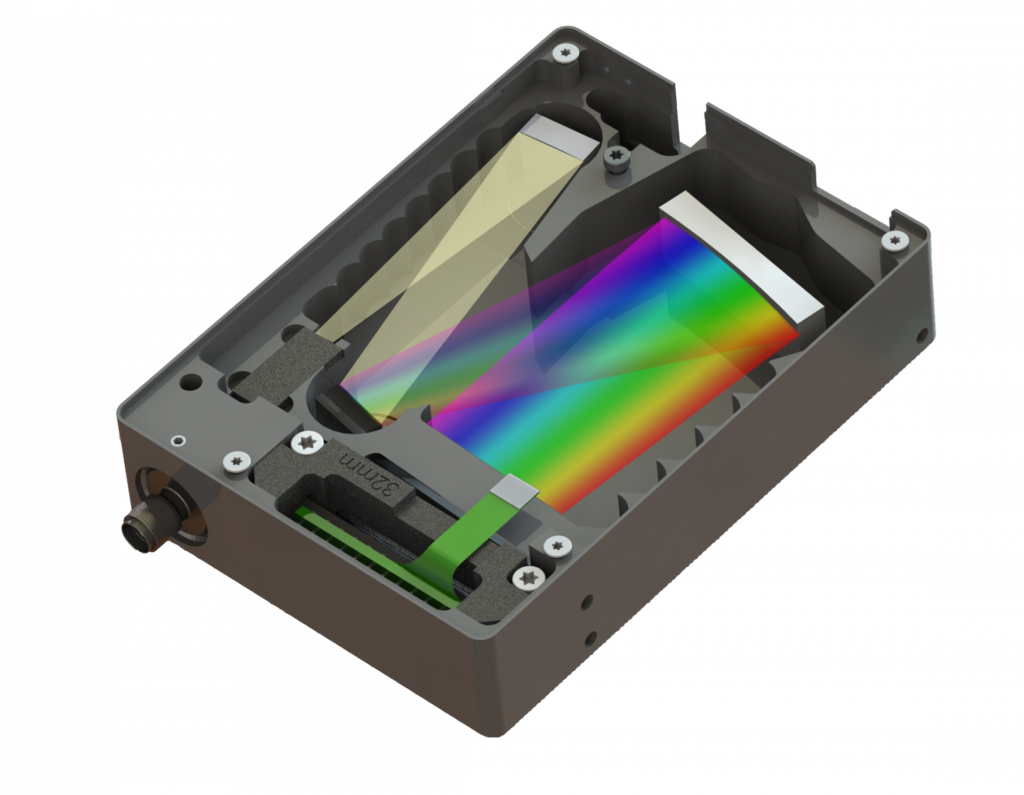

An effective analyser for fiber optic jobs have to include several essential functions that boost precision and functionality in diameter measurement. High-resolution optical sensing units are crucial for precise size analyses, enabling customers to identify even the least variations in fiber density. These sensing units ought to be complemented by innovative calibration systems, making sure constant efficiency throughout different problems and products.

Secondly, an easy to use interface is essential for assisting in convenience of procedure. This consists of user-friendly software application that permits smooth information input and output, along with aesthetic representations of the dimensions taken. A portable layout improves functionality in numerous area settings, making it easier to carry out assessments on-site.

In addition, the analyser ought to support numerous dimension modes, fitting numerous fibre types and applications. The capability to store and fetch historical data is another vital attribute, permitting individuals to track efficiency with time and make informed decisions.

Benefits for Fibre Optic Projects

Implementing a size analyser in fiber optic tasks provides significant advantages that substantially enhance task effectiveness and high quality. Among the primary benefits is the ability to make sure exact dimensions of fiber diameter, which is crucial for maintaining optimal performance in fiber optic systems. Exact size analyses aid in the identification of disparities that could lead to indicate deterioration or loss, therefore making sure top quality transmission.

Furthermore, making use of a diameter analyser enhances the quality control procedure. By automating dimension jobs, task groups can minimize the time invested in hand-operated assessments, resulting in faster project conclusion and decreased work costs. This effectiveness likewise permits more strenuous testing methods, resulting in improved product reliability.

In addition, uniformity in fibre diameter dimensions advertises compatibility with various other fibre optic parts, minimizing the danger of setup mistakes and enhancing overall system performance. The consolidation of a size analyser not only help in keeping market criteria yet also cultivates self-confidence in task deliverables.

Combination Into Existing Process

Incorporating a diameter analyser into existing process can significantly enhance the functional efficiency of fibre optic projects. By seamlessly integrating this innovation, teams can attain exact measurements that are critical to keeping the stability and efficiency of fiber optic systems. This combination enables real-time information collection and evaluation, which can be critical throughout the manufacturing and setup stages.

In addition, the capability to automate diameter measurement processes decreases the possibility for human mistake, making certain regular quality control throughout the job lifecycle. The data generated can be conveniently shared throughout platforms, assisting in cooperation among designers, specialists, and job managers. This availability improves decision-making and increases job timelines.

Picking the Right Diameter Analyser

When selecting a size analyser for fiber optic projects, it is vital to think about numerous crucial factors that straight impact measurement accuracy and operational effectiveness. Initially, the resolution and precision of the analyser must line up with the details requirements of your task. Greater resolution instruments can spot minute variants in diameter, website link which is vital for guaranteeing ideal efficiency in fibre optic systems.

For tasks with tight due dates, a diameter analyser that uses fast data acquisition can substantially enhance productivity. In addition, consider the analyser's compatibility with existing systems and software program.

One more essential variable is the range of diameters the analyser can accommodate. By very carefully assessing these elements, you can pick a diameter analyser that enhances the performance and precision of your fibre optic tasks.

Final Thought

In final thought, the combination of an efficient diameter analyser is extremely important for enhancing fiber optic tasks. Accurate diameter dimensions make certain optimum performance and integrity while lessening setup errors. Advanced functions help with real-time data collection and compliance with market standards, eventually raising the top quality of deliverables. By focusing on the selection and application of a proper analyser, task effectiveness is significantly boosted, leading the way for successful end results in fibre optic Full Article applications.

A cable's diameter straight influences its capacity to send light effectively; variances from the specified diameter can lead to boosted attenuation, which influences the general efficiency of the network.

Report this page